3D RENDERING IN INDUSTRIAL DESIGN

At Atienza & Climent, we have been developing and manufacturing industrial products for more than 25 years through different industrial production and manufacturing processes.

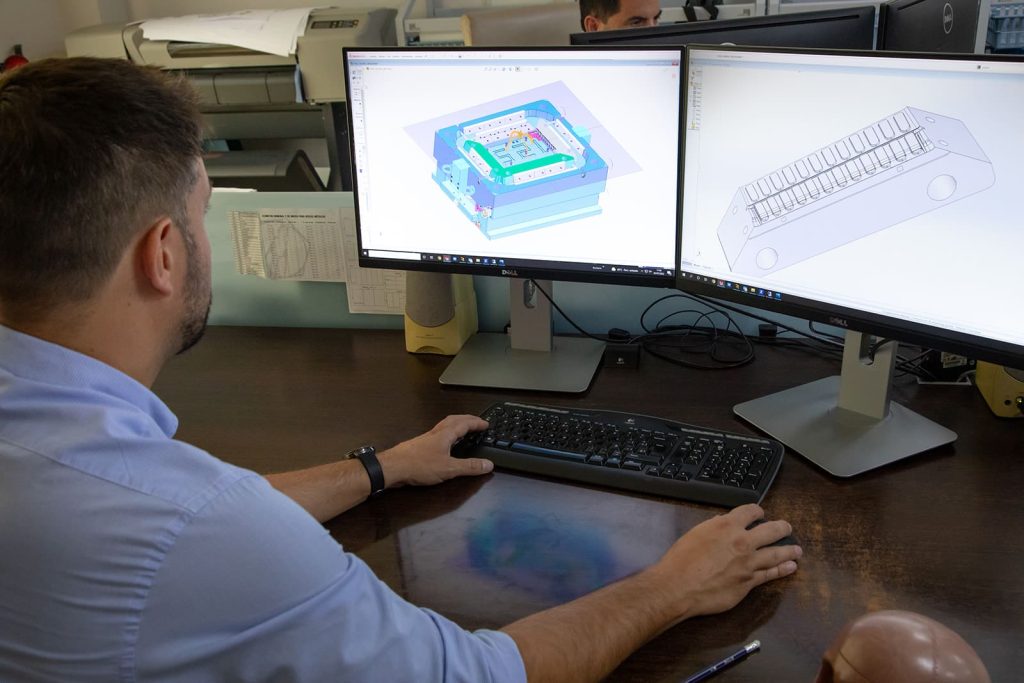

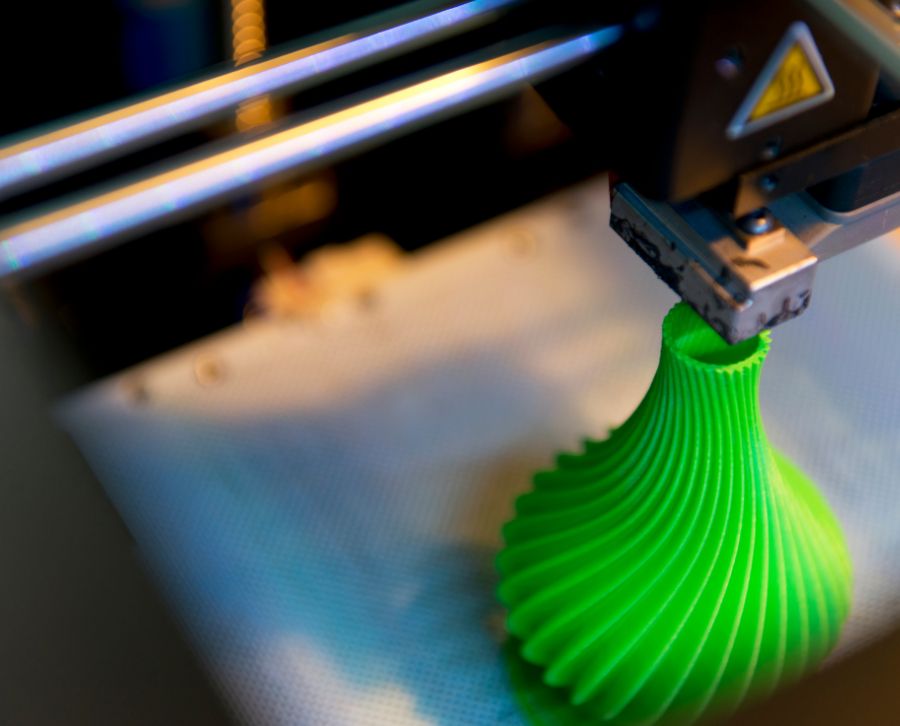

One of the first and most important phases for the successful manufacture of a product is product design. And within this stage of production, one of the most innovative techniques that we work with the most is the 3D rendering of products.

Contact us and tell us about your project. We manufacture your ideas.

3D rendering services for product development

We offer 3D rendering services of the products that will later be manufactured, to improve them or to show them to customers.

This technique is very effective to be able to solve errors in the final product before the actual manufacturing. Therefore, as a company specialised in product development, we use this method before starting the manufacturing process.

Do you need to manufacture a product or a specific part? We help you from the first design stage to the distribution of the manufactured and packaged product itself. We are mainly specialised in the toy sector, collectors’ items and promotional items, although we can manufacture any type of object.

What is the 3D rendering of industrial products

The 3D rendering of a product in industry has become an essential tool for the creation of realistic and accurate images of products and environments. In other words, it allows us to see what the product to be manufactured will look like before it is made.

Therefore, by visualising the product and manipulating it before it is produced, it allows errors to be detected and the design to be improved at an early stage in the development process. Thanks to advances in rendering technologies and software, this methodology has become an increasingly valuable tool in the industry.

Benefits of using 3D product rendering in industry

This technique, used in a wide variety of fields from architecture and engineering to product design, helps companies improve performance, productivity and cost savings.

3D rendering allows integrated product development companies to create objects as realistically and accurately as possible, so that they can visualise, experiment with and evaluate the design before manufacturing.

It is used in the design of products and parts, from the conceptual design to the production stage, being a complex and very complete process. In this way, it helps us to test the product with different designs and materials.

At Atienza & Climent we use this 3D rendering process as part of the development process, after the product design. It is a fundamental part prior to the mass production of the products we make for our clients. In this way, we contribute to greater precision in manufacturing, greater economic savings and greater profitability.

by

by