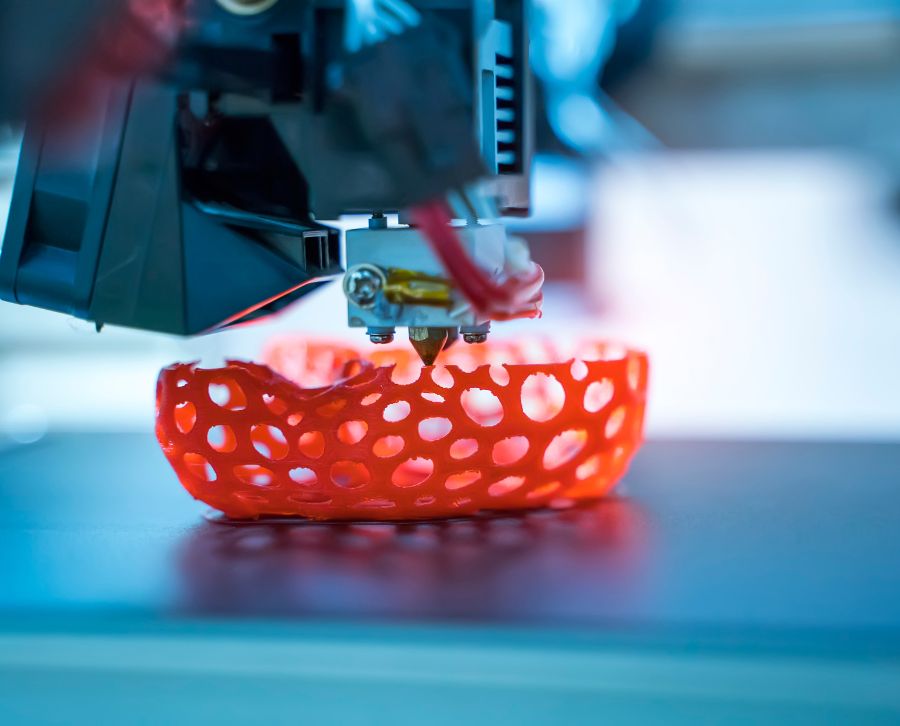

Sustainable materials are positioning themselves as a more environmentally friendly alternative in the manufacturing sector. Innovation and the constant study of raw materials that have a less negative impact on the environment are gaining important ground in processes such as 3D printing.

At Atienza & Climent we have been offering comprehensive industrial development services and 3D printing services with sustainable materials for more than 30 years. We are aware of the need to reduce pollution in manufacturing processes. In this article we tell you how it is possible to achieve this goal.

Sustainable materials in 3D printing

Investing in sustainable 3D printing technology not only is beneficial for the environment, but also offers great advantages to manufacturers. Sustainable materials are designed to reduce environmental impact and deliver the highest quality results.

These materials, such as biodegradable plastics and recycled filaments, offer a wide range of options for designers and manufacturers, in addition to their contribution to sustainability.

Benefits of using sustainable materials

Choosing sustainable materials in 3D printing is not only an environmentally responsible decision, it also offers a number of benefits for both manufacturers and the wider environment.

Here are some of the most significant ones:

- Reduced environmental impact: by using biodegradable, recycled or plant-based materials, the amount of plastic waste and reliance on non-renewable resources is reduced.

- Long-term cost savings: despite a possible slightly higher initial cost, they can result in significant savings over the life cycle of the product due to their durability and strength.

- Positive brand image: adopting sustainable practices can enhance a company’s reputation and commitment to environmental responsibility, attracting customers who value sustainability.

- Flexibility and versatility: they offer a wide range of design options and applications, allowing the creation of customised and functional products.

- Compliance with environmental regulations: by using eco-friendly materials, companies can comply with increasingly stringent environmental regulations and contribute to a cleaner environment.

Types of sustainable materials for 3D printing

Today, 3D printing can be done with a wide range of sustainable materials that allow the creation of innovative and environmentally friendly objects.

Green plastics for 3D printing

They are made from biodegradable or recyclable materials. These materials offer high strength and durability, ideal for many 3D printing jobs.

Among the most common are:

- PLA (Polylactic Acid): made from renewable resources such as corn starch or sugar cane, PLA is biodegradable and breaks down under proper composting conditions.

- PETG (Polyethylene terephthalate glycol): although not biodegradable, it is highly recyclable and can be reused multiple times, thus reducing its environmental impact.

- Biopolymers: these polymers are designed to be fully biodegradable and compostable, offering a sustainable option.

Biodegradable and compostable materials

Biodegradable and compostable materials are an increasingly popular choice for sustainable 3D printing. These materials break down naturally in the environment, reducing the accumulation of plastic waste.

- PHA (Polyhydroxyalkanoates): these polymers are fully biodegradable and break down in industrial or domestic composting environments.

- Biocomposites: blends of natural materials such as wood, hemp or cellulose fibres with biodegradable polymers, creating strong and sustainable materials.

- Corn starch: used as a raw material for the manufacture of 3D printing filaments, corn starch is biodegradable and decomposes under composting conditions.

Recycled materials for 3D printing

Knowing how to use recycled materials in 3D printing is a must, as it is an effective way to reduce the amount of plastic waste and promote the circular economy.

Here are some of them:

- Recycled PLA filament: sourced from 3D printing waste or other PLA products, reducing the need for new resources.

- Recycled PET: comes from plastic bottles or other PET products, and is used in the manufacture of 3D printing filaments.

- Recycled ABS: offers a sustainable alternative to conventional ABS, using plastic recovered from various products.

Challenges and solutions in sustainable 3D printing

This component manufacturing technique faces numerous challenges such as energy consumption and waste management. However, there are innovative solutions that can counteract these effects. The use of more efficient technologies and recycling practices not only improve sustainability in production processes, but also reduce the environmental impact of 3D printing, driving a more sustainable and responsible future for the industry.

Industrial 3D printing and rapid prototyping companies need to be aware of the current issues and commit to using sustainable materials in the manufacture of their products.

by

by