Accelerating time to market helps companies become more influential in the market and establish themselves as leaders. Why? Because it lets them get ahead of the competition and be seen as an innovation benchmark.

Consumer needs change, and you must be ready to offer solutions. Imagine you design an innovative product, but the launch timeline stretches too long and another company beats you to market.

You would undoubtedly lose the chance to surprise customers and generate more revenue. That said, speeding up time-to-market can seem complex—but at Atienza & Climent, we know how to do it.

The challenge: launching a new product in record time

Everything starts with the idea! But the real challenge is turning it into reality and bringing it to market. Any company that has faced the task of launching a product knows it involves multiple processes.

One of the most important is time-to-market. If it is reduced, the company can gain solid advantages that put it ahead of the competition. These include higher revenue and greater authority in the market.

Client company profile and industry

The first step is to analyze the company’s profile and the industry in which it operates in depth. This helps us understand the product’s level of complexity and all the technology required to manufacture it.

It also helps assess how mature the sector/market is to adopt the product and, above all, how the company’s internal structure aligns with it—and whether it accounts for everything needed to meet the planned timelines.

The problem: delayed validation and production delays

Both late validation and production delays undermine a quick time-to-market (i.e., a fast commercialization timeline). Beyond increasing operating costs, they also hurt competitiveness.

The most common causes include planning errors, poor communication, and late identification of raw materials issues or defective materials. However, the causes can vary widely depending on the company’s sector.

That’s why it is crucial to understand the client’s profile in depth. This allows us to spot situations and processes that could constrain the product’s production—and prevent them from impacting time-to-market.

Objective: shorten timelines without compromising quality

Reducing time-to-market must never compromise product quality—and this is our strongest principle. The goal is to optimize every process involved in development without affecting quality parameters.

Atienza & Climent’s solution: agile prototyping and custom technical design

Once all the above areas have been addressed, it’s time to turn the company’s idea into reality. How? Through agile prototyping and custom technical design.

Rapid CAD design with client-validated iterations

CAD modeling is one of the most useful tools for producing prototypes tailored to requirements and expectations. That’s why it’s one of the techniques we most frequently use at Atienza & Climent.

Thanks to this design approach, we generate rapid iterations for the client to validate, which speeds up the move into the production phase.

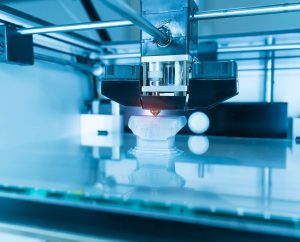

3D printing for functional testing

Besides design, product functionality is a key area to evaluate—and we achieve this through 3D printing. This is essential because it lets us detect faults and errors before sending the product to manufacturing.

It also helps reduce the need to adjust production lines later on—something that often requires significant investment and can even affect the product’s and the company’s image in the market.

When we 3D-print a product, we evaluate its functionality in all dimensions—something that would take far longer and many more iterations with traditional techniques.

Engineering adjustments to reduce manufacturing errors

Design feasibility is another important point. We provide technical modifications that optimize the design to prevent common failures that can appear in the later stages of product development.

Results achieved: weeks saved and early validation

Saving weeks and securing early validation are crucial when a product launch is in sight—and we achieve both by implementing the techniques described above.

Comparison: traditional process vs. Atienza & Climent’s solution

For years, companies relying on traditional techniques took many months to bring a product to market. Validation timelines and adjustments dragged on too long, stalling the idea overall.

At Atienza & Climent, we identify the weak points of traditional processes and reinforce them. This way, we leverage the strengths of the traditional approach while complementing it with the new—the best of both worlds.

Real reduction in time-to-market (number of days/weeks)

By implementing prototyping and optimization in the design phase, we achieve a substantial reduction in launch timelines. In many cases, we’ve cut weeks off time-to-market without affecting quality at all.

Technical feedback from the client

Clients have primarily valued the efficient communication throughout the process. They also highlight that the cost savings were significant and that early adjustments led to successful mass-production runs.

Keys to success: agility, precision, and collaborative teamwork

Teamwork has enabled us to achieve strong goals and milestones over the years. All our professionals have agile profiles, exceptional attention to detail, and a deep commitment to collaborative work.

Multidisciplinary technical team

Because we work with clients from different industries and sectors, we have built a multidisciplinary technical team.

Our designers, engineers, and manufacturing specialists are equipped to support clients across diverse fields. They also have strong adaptability to understand each customer’s specific needs.

Full integration between design and prototyping

CAD modeling, together with each functional test, enables full integration between design and prototyping. In addition, adjustments are made with greater precision and speed to avoid potential rework.

Continuous communication with the client

Listening carefully to our clients’ needs and adapting our processes accordingly has been the key to our success. We also make sure to stay in constant communication.

It’s important to us to keep the client informed throughout every stage of production. This way, we can work toward meeting their expectations.

Do you need help accelerating the time to market for the product you have in mind? At Atienza & Climent, we have the expertise and equipment to deliver concrete solutions today.

Frequently Asked Questions

Everything related to the time-to-market KPI often raises a few common questions. In this section, we’ve gathered some of the most frequently asked ones. Take a look!

When we accelerate the time-to-market process, the company can take advantage of specific market needs at the right moment.

It can also offer consumers a solution to their needs before competitors do. This results in increased competitiveness, stronger authority, and of course, higher revenue.

Time-to-market can be affected by communication errors and bottlenecks, as well as design flaws that arise in later stages of production and issues with materials or raw inputs.

Implementing techniques like 3D printing and CAD design helps eliminate the errors that typically cause time-to-market to stretch too long.

It also improves internal communication and helps identify which tasks are limiting within the production chain, allowing you to prevent bottlenecks.