At Atienza & Climent, as experts in product development and prototype manufacturing, we would like to explain the 3d sculpture service to you in more detail. It is a process that offers great precision and detail in industrial development.

Professional 3D sculpture service H2

Atienza & Climent, which specialises in the comprehensive development of product, can provide a professional 3D sculpting service. This is one of the phases of our initial prototyping process.

We design, develop, manufacture, decorate, stock and distribute any type of product that can be mass-produced using techniques such as plastic injection, zamak injection, injection blow moulding…

Above all, we are experts in the toy sector, hospital equipment, promotional items and collector’s items. We also offer a complete service for other types of products.

Do you have an idea or project and need to manufacture part of the product? Contact us and we will make it happen.

What are industrial 3D sculptures?

3D sculpting is a technique widely used in product development, as it allows the creation of highly accurate three-dimensional models. These can be used for prototyping, design testing and evaluating the performance and ergonomics of a product.

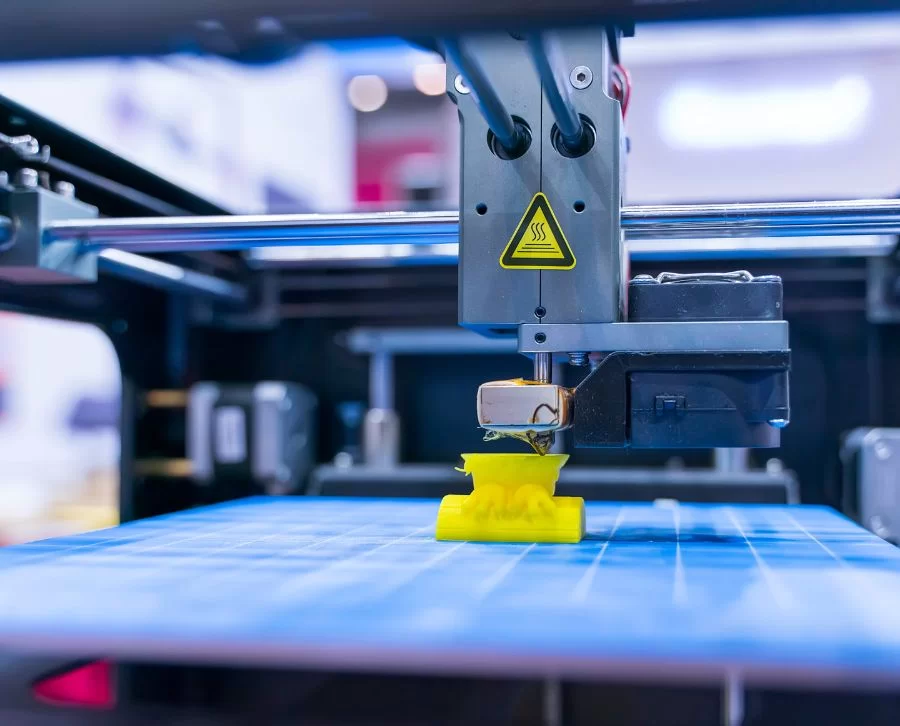

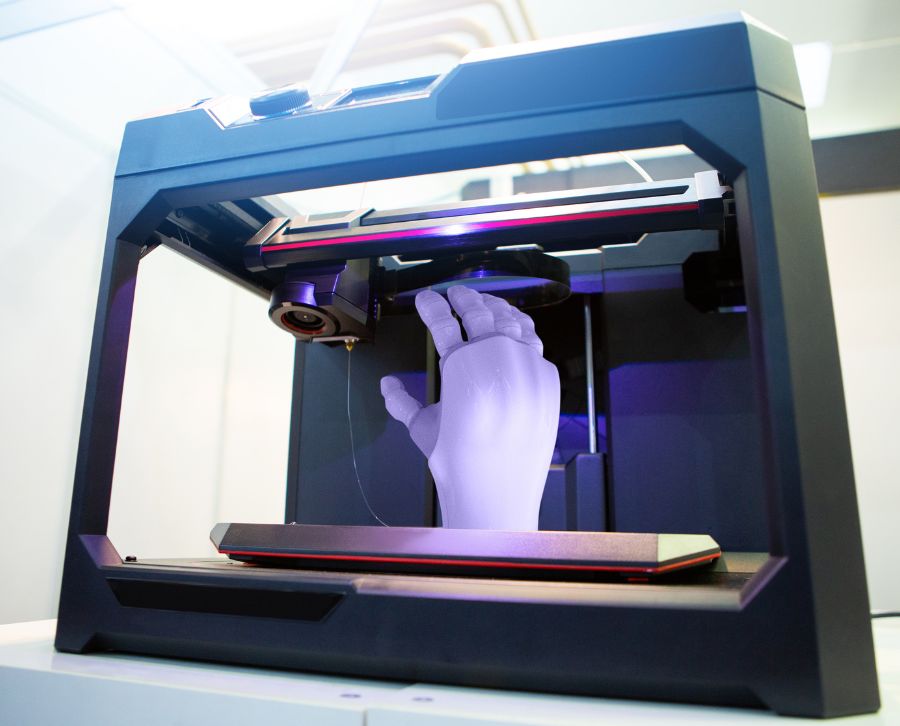

There are several techniques and tools available to create 3D sculptures, including 3D digital modelling, 3D scanning and 3D printing. Digital 3D modelling involves creating a digital model from scratch using specialised software, while 3D scanning involves creating a model from a real object using 3D scanners. 3D printing, on the other hand, allows physical objects to be created from a digital model using 3D printers.

At Atienta & Climent, we also offer 3D printing and 3D scanning services, as part of the integral process when designing and developing a product.

Applications of a 3D sculpture

In particular, in the industrial sector which is specialised in product development, 3D sculptures can be used in the manufacture of products using techniques such as plastic injection moulding or metal casting. In addition, they are also used to create models and prototypes for the presentation and promotion of the product to be manufactured.

They are a powerful tool in product development because of their capability to create highly accurate and detailed models, and because of their versatility in the manufacture and presentation of products. All of the above allows us to work in a well-organised way.

Therefore, it is a very useful tool when designing prototypes as it allows designers and manufacturers to evaluate and test the appearance and characteristics of the final product.

They can also be used to create mock-ups or scale models of existing or developing products. A very useful feature for presentations or to visualise how the product would look in different environments or situations, as well as to analyse it from different angles and evaluate its function and performance.

This can be especially useful in the development of products that require a high degree of precision and tolerance, such as machine parts or products that require a lot of safety and monitoring. For example, in the case of the manufacture of moulds or toy parts that must meet different requirements in order to be sold on the market.

by

by