Mass production is a procedure widely used in industry for mass production of products in large quantities in the most efficient way.

Chain production is characterised by the standardisation of processes, the repetition of tasks and the use of specialised machinery.

This production system seems to be closely linked to the automobile industry, although it is now used in all industries. It was the method that Henry Ford implemented in his car factory in 1913, demonstrating its enormous potential. Three decades later, the Toyota company improved the production line with its Just In Time (JIT) method.

Types of mass production

There are some differences between the different types of mass production. Each method is adapted to the product in question, depending on its characteristics, or the demands of the customer.

Here are some common types of mass production:

- Flow production. The product is manufactured on an assembly line where each unit is assembled by several workers or workstations. Each group of workers is responsible for a specific task in the manufacturing process. The product moves from one station to the next until it is completed. This method is most often associated with the concept of mass production.

- Batch production. In this case, a complete batch is produced at the same time. Products are grouped and manufactured in a single operation before moving on to the next batch. This method is used when there is a demand for a particular product and multiple units can be produced at the same time.

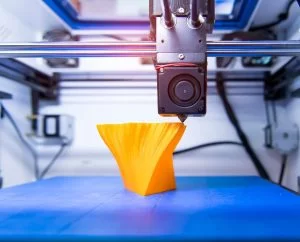

- On-demand production. In this type of production, each unit of the product is manufactured individually according to the customer’s specifications. In contrast to flow and batch production, on-demand production involves the production of unique products in accordance with the customer’s demands. This requires more time and effort to adapt to each customer’s specific requests.

Advantages and disadvantages of mass production

Like any manufacturing system, mass production has many important advantages, but also some disadvantages.

Advantages of mass production

Mass production offers several advantages that make it an attractive option for many companies:

- Cost reduction. By producing in large volumes, the production costs of each unit tend to decrease. This is a basic principle behind the concept of economy of scale, where high production volumes allow for better efficiency and more equitable distribution of resources.

- Increased productivity. By standardising processes and tasks, mass production allows for higher productivity. Repetitive tasks become more efficient while workers acquire specialised skills in the specific tasks they perform. This is something that can be seen on a small scale in everyday tasks.

- Quality is maintained in every product. Standardisation and process control in series production help to ensure consistent quality in all manufactured products. This is especially important in car manufacturing, where the safety and smooth running of each unit is paramount.

- Increased responsiveness to demand. With increased production capacity, companies can respond quickly to possible increases in market demand. This is especially useful in sectors where demand can fluctuate rapidly on a seasonal basis.

Disadvantages of industrial mass production

Mass production also has some disadvantages to consider:

- Lack of flexibility. Due to standardisation and repetition of tasks, mass production can have difficulty adapting to changes in product requirements. Therefore, when modifications have to be made to a product, it can be more costly.

- Risk of obsolescence. In an environment of rapid technological advances and changing markets, mass-produced products may be at risk of becoming obsolete more quickly. This can be a problem if a company finds itself with an inventory of products that are no longer in demand by customers, which is common in today’s technology industry.

- Higher initial investment. Implementing mass production requires significant upfront investment in specialised machinery, tooling and production systems. This can be a financial challenge that smaller companies cannot afford.

Despite its disadvantages, mass production is still used in many industries, often in combination with other production methods, and has proven to be an effective method for producing large volumes of products in a cost-efficient manner.

Mass production, key in the industrial sector

A current example of the successful application of mass production in combination with large-scale manufacturing is the production of smartphones. Thanks to mass production, companies can produce smartphones on a large scale, which has helped to reduce production costs and make them more accessible to consumers.

The advantages of this type of production in terms of efficiency, productivity and quality make it the best option for many companies. By implementing the different types of mass production, companies can take full advantage of this approach to boost their success in the market.

At Atienza y Climent we are experts in mass production, which is why we design and develop projects for all types of industrial sectors. If you are interested in more information, please contact us.

by

by