The word “novelty” has always been part of toy catalogues as a lure for children and parents. But novelty is also very present in toy design and manufacturing, a sector that innovates every year by following trends in other industries and creating its own.

For example, advances in electronics and computing in recent years have made it possible to design and create interactive and intelligent toys, which increasingly incorporate sensors and even Internet connectivity.

Advances in materials have also revolutionised the industry in several aspects: quality, safety and manufacturing processes. New plastics are stronger, safer and more sustainable.

On the other hand, personalisation is one of the trends of this second decade of the 19th century and is possible thanks to the sum of all the techniques developed previously.

Design and development techniques

Game and toy design and development companies need to innovate if they want to compete in the market.

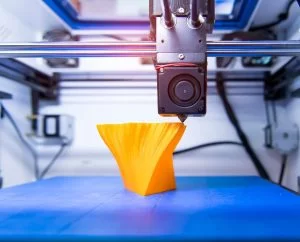

3D printers, advanced design software and CNC machinery are improving the prototyping and production process.

In addition, creative design is evolving thanks to the study of the child user, marketing and research applied to educational toys.

All these factors are enabling the development of physical toys that can compete or complement the powerful video game market.

Rapid prototyping

Rapid prototyping using 3D printing allows functional prototypes to be created in an agile way to test and validate ideas and designs. This significantly accelerates design processes, reduces costs, and facilitates continuous improvement.

In addition to 3D additive manufacturing, materials such as foams, silicones or waxes are used to quickly obtain volumes and shapes to test the ergonomics and functionality of the prototypes before moving on to the production process.

Automation in production (H3)

Automation in toy production is increasing thanks to the use of collaborative robots (cobots), machine vision systems, internet of things (IoT) and other advanced control systems.

Automation increases process efficiency and flexibility, reduces costs and errors, and improves the quality and consistency of the final product. Integration of machines, data and systems is essential.

STEM toys

STEM toys aim to awaken in children vocations related to science, technology, engineering and mathematics, and boost skills such as problem solving, critical thinking and creativity.

Some examples are construction sets, educational robotics or science kits to encourage practical and fun learning of the concepts encompassed by the acronym STEM (science, technology, engineering, maths).

Demand for this type of toy is growing, and new brands and franchises are emerging that focus solely on this niche, so companies are looking to innovate in this category.

Augmented reality toys

Augmented reality (AR) toys merge animated and interactive digital elements with the real world to create an immersive play experience.

Through an app, children can see a virtual 3D character projected in the environment and interact with it. This opens up new and creative play possibilities that combine the digital with the physical.

Virtual reality toys

Virtual reality (VR) toys have the ability to transport the user into a fully immersive and interactive environment.

They provide great educational and entertainment value by allowing adventures and experiments that would be impossible in the real world. It is a challenge to adapt these experiences to child users in a safe way.

Innovative materials

To innovate in sustainability, companies are using environmentally friendly and recyclable materials such as biodegradable plastics, wood, cardboard, etc. On the other hand, there are new processes such as selective laser sintering, which optimises the use of raw materials.

In addition, smart materials are being researched to enable new digital interactions, such as connected toys.

Quality and safety

Companies invest heavily in improving quality and process control to innovate safe and attractive products.

In addition, they must comply with stringent safety regulations that touch on various mechanical, chemical, hygienic, radioelectric, flammability, etc. aspects. Currently, exhaustive tests and certifications are carried out.

Traceability and supplier control are also key to guaranteeing quality and quickly identifying potential problems.

Sustainability and ethics

Finally, toy manufacturers are committed to introducing sustainable production methods through renewable energy, waste reduction and recycled and biodegradable materials. The circular economy is also booming in this sector.

Social responsibility through ethical and transparent practices throughout the supply chain is also a priority.

In conclusion, the toy industry is constantly reinventing itself to offer innovations that satisfy both parents and children.

by

by